Products

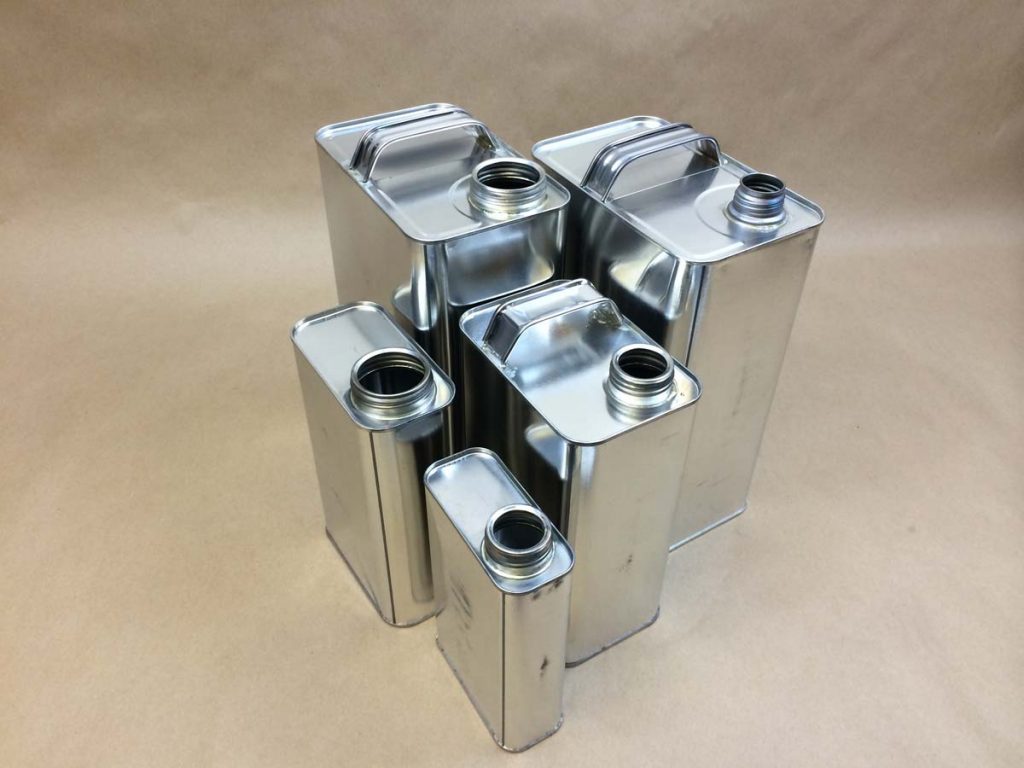

General Purpose Container

JNBL involved in general purpose container making from its inception. Process automation and purpose dedicated raw materials are the essence of JNBL’s differentiation. JNBL is serving in different product category with verity of pack sizes. Currently we are manufacturing general purpose containers for: Paints, Thinner, Inks, Lubricant Oils, Adhesives and hair oils. Pack size ranging from 100ml to 25Ltr. and rectangular container ranging from 2Ltr. to 5Ltr.

Food Grade Container

Decorative Container

Container R&D

JNBL recently introduce close mouth ink container with tri-sure cap. This close mouth container volume ranging from 20Ltr. and 25Ltr. Metal handle is developed for easy handling and this close mouth container enables stacking to reduce space constrains. Rectangular container is the best preferred for Thinner and Lubricant packaging. JNBL developed full automated production machineries for rectangular container making. This automated process enables premium product quality and zero leakage due to bending.